2.15 Corner Trim In Flattened State 00:03:54. 2.05 Patterning And Mirroring Features 00:02:38. 2.02 Bend Allowance And Bend Tables 00:06:19. 1.04 How To Access Your Working Files 00:01:15. 1.01 Introduction To SolidWorks Sheet Metal 00:02:48. Working files are included, allowing you to follow along with the author throughout the lessons.

Finally, the course concludes with a chapter to help you prepare for the SolidWorks Sheet Metal Certification exam.Once you have completed this computer based training course, you will be fully capable of creating sheet metal parts in SolidWorks, as well as prepare for and pass the CSWPA - Sheet Metal exam.

You will also learn how to create advanced sheet metal features, such as multibody sheet metal parts and lofted bends. This video tutorial also covers how to convert an existing part into a sheet metal part, as well as how to create sheet metal drawings from sheet metal parts. From there, Dean will teach you how to apply and modify sheet metal forming tools. This course is designed to help users prepare for and successfully complete the SolidWorks Sheet Metal Certification (CSWPA - Sheet Metal) exam, meaning a fundamental understanding of SolidWorks is required.You will start by learning how to create sheet metal parts, including a base flange, closed corner, and a miter flange.

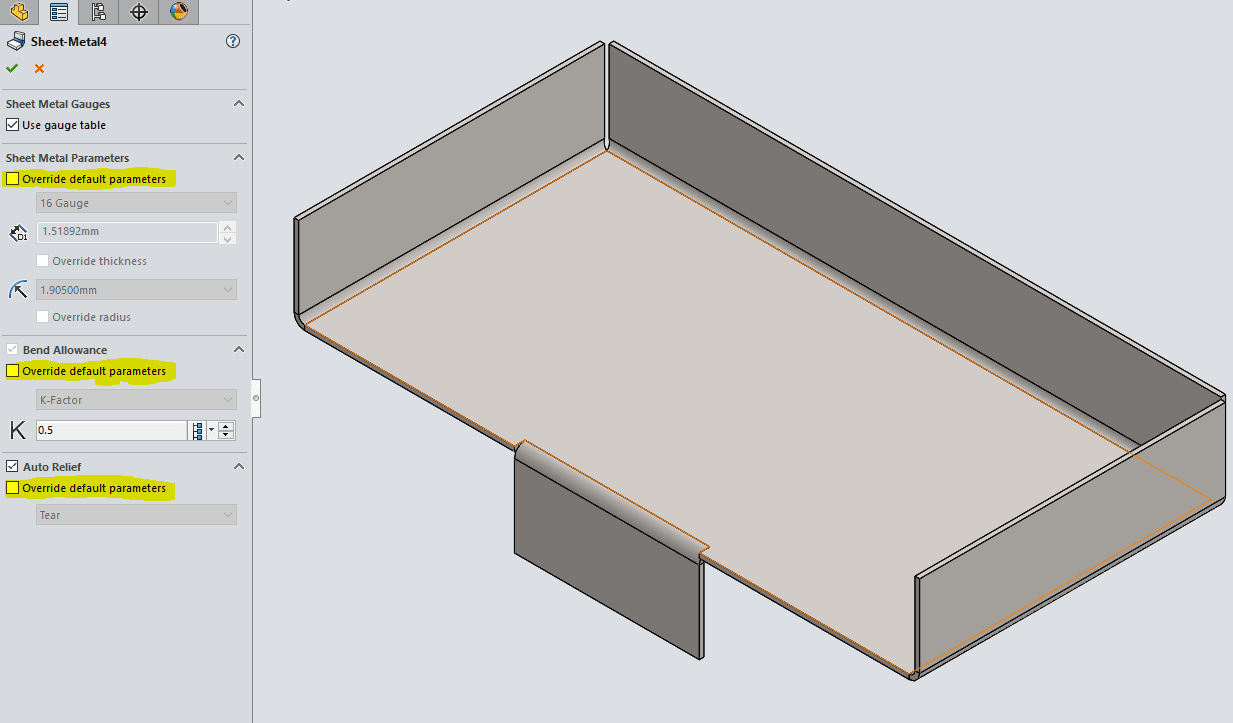

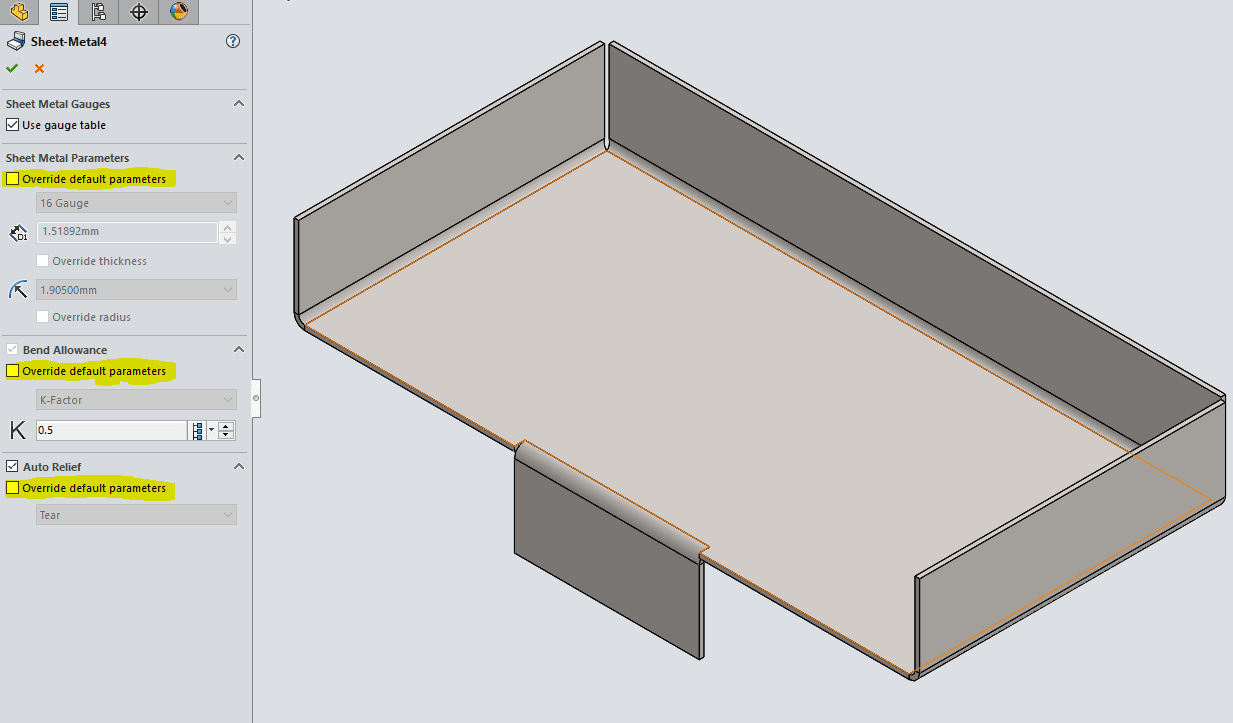

The part is now converted to sheet metal andĬan be viewed as a folded or flattened part.In this SolidWorks 2015 - Sheet Metal training course, expert author Dean Kerste will teach you how to navigate the SolidWorks sheet metal environment. For this example, I have selected an Open Butt corner type with a 1mm gap Where two edges meet the gap and type of corner Open Butt, Overlap, Underlap, can be selected for all or individually. A “Rip Sketch” will cause a “Rip Edge” to be added at a chosen location based on the geometry of the sketch. Due to the structure of this component it is impossible to bend the fourth edge to complete the shape,so we’ll need to use a “Rip Sketch”. SOLIDWORKS will thenĪutomatically select “Rip Edges” which create cuts in the sheet metal body. This decides which face the remaining faces are bent from.Įdges” to define the bends in the sheet metal part. Select a fixed face, here I have selected the bottom face has been selected as the fixed entity. In this example, I have used a sample table for steel and selected 14 gauge with a 2.54mm bend radius. Define the desired thickness and bend radius either by selecting a gauge table or by entering it manually. Lofts. The tool also works well on imported Sheet Metal files, to use it

Has been created using standard part modelling features such as extrudes and This is a useful tool if the initial part User to quickly convert parts into sheet metal models, from there a flat

0 kommentar(er)

0 kommentar(er)